|

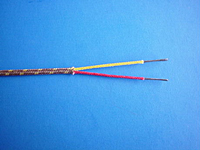

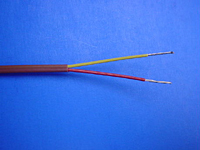

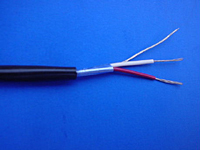

Fiberglass (GG) 950°F Wire

Most popular and widely applied of all glass insulations. A color-coded fiberglass braid saturated with a high performance resin is used for insulation of the single conductors and jacket.

Performance Features

Designed for continuous use at temperatures to 950°F (480°C) intermittent use to 1200°F (540°C)

Good Moisture and chemical resistance; fair abrasion resistance

Applications

Heat Treating

Glass & Ceramic Kilns

Foundries

Extensive applications in aluminum processing

|

|

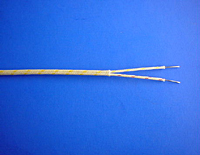

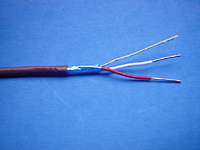

High Temperature Fiberglass (HGHG) 1200°F Wire

A high temperature, high tensile strength fiberglass, either color-coded or with tracer yarn, is braided on both the single conductors and the overall jacket. both are impregnated with a 500°F modified resin saturant.

Performance Features

Designed for continuous use at temperatures to 1200°F (650°C) intermittent use to 1450°F (790°C)

Good Moisture and chemical resistance

Applications

Preheating & stress relieving of forging

Heat treating for annealing, aging, or hardening

Furnace temperature surveys

|

|

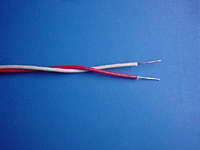

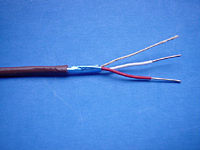

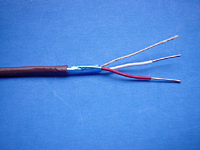

Refrasil (Vitreous Silica) (RR) 1800°F Wire

High temperature silica fibers are braided on the single conductors as well as the overall jacket. Because saturant is not used, this product is not recommended for abrasive applications. Each conductor as well as the overall jacket is braided with this high temperature yarn to provide maximum flexibility at extremely high temperatures. A tracer is braided into insulation for polarity and calibration identification.

Performance Features

Designed for continuous use at temperatures to 1800°F (980°C) intermittent use to 2000°F (1095°C)

Not recommended for applications where insulation may be subjected to abrasion.

Applications

Furnace Survey thermocouples

Heat treating

|

|

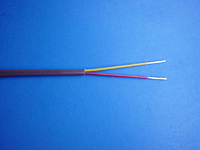

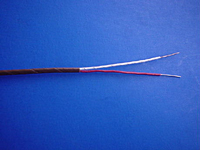

High Temp "S" Glass (STW) 1200°F Wire

A high temperature, high tensile strength, extra heavy fiber glass yarn is braided over each conductor. The insulated, color-coded conductors are impregnated with high temperature modified resin and twisted to form a pair. This product construction does not include an overall jacket.

Performance Features

Designed for continuous use at temperatures to 1200°F (650°C) intermittent use to 1450°F (790°C)

Good abrasion resistance

Easily stripped and terminated

Economically practical for short-duration applications

Applications

Homogenizing furnaces for billet preheating

Furnace temperature surveys

Heat treating

|

|

Ceramic Fiber (CFCF) 2200°F Wire

Highest temperature flexible insulation available. The braided yarn is a composition of the oxides of alumina, boric and silicone. Each conductor as well as the overall jacket are braided with this high temperature yarn to provide maximum flexibility at extremely high temperatures.

Performance Features

Designed for continuous use at temperatures to 2200°F (1205°C) intermittent use to 2600°F (1430°C)

Good abrasion and chemical resistance

Applications

As a replacement for beaded thermocouples

Heat treatment

Coke ovens

Soaking pits

Furance survey thermocouples

Brick & tile kilns

|

|

Ceramic Fiber (MCFCF) 2200°F Wire

This construction has a mica barrier tape applied to each single conductor prior to being insulated with the ceramic fiber yarns. The construction is identical to the CFCF construction except for the addition of a light jacket saturant and the mica tape, which protects against potential shorting from the back carbon residue which forms when the product is used in applications where the air is limited, such as thermocouples in protection tubes. The mica may also provide moisture protection during temperature cycling.

Designed for continuous use at temperatures to 2200°F(1205°C) intermittent use to 2600°F (1430°C)

Applications

For use in closed tubes or protected atmosphere

As a replacement for beaded thermocouples

Heat treatment

Coke ovens

Soaking pits

Furance survey thermocouples

Brick & tile kilns

|

|

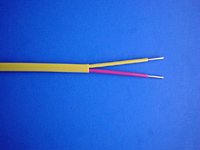

Teflon® Extruded FEP (TT) 400°F Wire

Color-coded FEP Teflon® is extruded over each single conductor. The single insulated conductors are laid parallel and insulated with an extruded jacket of FEP Teflon®

Performance Features

Designed for continuous use at temperatures to 400°F (205°C) intermittent use to 500°F (260°C)

Most economic and popular of the Teflon® constructions.

Excellent low-friction jacket facilitates easy pulling of wire through conduits.

Applications

Power generating plants

Petroleum plants

Field heat treating |

|

Teflon® Extruded Shielded FEP (TAT) 400°F Wire

Color-coded FEP Teflon® is extruded over each single conductor. The single insulated conductors are twisted with a stranded drain wire, and twisted construction is covered with an aluminum/mylar tape.

Performance Features

Designed for continuous use at temperatures to 400°F (205°C) intermittent use to 500°F (260°C)

Twisted/Shielded construction minimizes electrical interference.

Excellent abrasion, moisture and chemical resistance.

Applications

Power generating plants

Petroleum plants

Field heat treatin |

|

Fused TFE Tape (TFTF) 500°F Wire

A double wrap of heat-fused TFE tape is spirally applied over each single conductor and as an overall jacket. Duplex construction

Performance Features

Designed for continuous use at temperatures to 500°F (260°C) intermittent use to 600°F (315°C)

Exhibits all the advantages of an extruded product while providing the additional temperature rating.

Excellent moisture and chemical resistance; good abrasion resistance.

Applications

Petroleum plants

Power plants

Aircraft bonding

Glass, ceramic & brick applications

|

|

Fused Shielded TFE Tape (TFATF) 500°F Wire

A double wrap of heat-fused TFE tape is spirally applied over each single conductor. Insulated conductors are twisted with a stranded drain wire and the twisted construction is covered with an aluminum/kapton tape. The outer jacket consists of double-wrapped heat-fused tape.

Performance Features

Designed for continuous use at temperatures to 500°F (260°C) intermittent use to 600°F (315°C)

Exhibit all the advantages of an extruded product while providing the additional temperature rating.

Excellent moisture and chemical resistance; good abrasion resistance.

Twisted/Shielded construction minimizes electrical interference.

Applications

Petroleum plants

Power plants

Aircraft bonding

Glass, ceramic & brick applications

|

|

Teflon® Extruded PFA (PFPF) 500°F Wire

Color-coded PFA Teflon® is extruded over each single conductor. A PFA Teflon® jacket is extruded over the insulated parallel singles to form a duplex construction.

Performance Features

Designed for continuous use at temperatures to 500°F (260°C) intermittent use to 550°F (290°C)

Provides the highest temperature rating of our extruded products.

Excellent moisture and chemical resistance; good abrasion resistance.

Very smooth finish on outer jacket.

Applications

Food processing plants

Glass, ceramic & brick plants

Power plants

|

|

Teflon® Extruded Shielded PFA (PFAPF) 500°F Wire

Color-coded PFA Teflon® is extruded over each single conductor. Insulated conductors are twisted with a stranded drain wire, and the twisted construction is covered with an aluminum/Kapton tape. A PFA Teflon® jacket is extruded over the shielded pair.

Performance Features

Designed for continuous use at temperatures to 500°F (260°C) intermittent use to 550°F (290°C)

Twisted/Shielded construction minimizes electrical interference.

Excellent moisture and chemical resistance; good abrasion resistance.

Applications

General plant installations

Aerospace

Glass, ceramic & brick plants

Power generating

|

|

Kapton® Tape (KK) 600°F Wire

Very tough, durable double wrap of heat-fused polyimide tape is applied over each conductor. Each insulated single conductor is coated with an ANSI color coded polyimide varnish. The jacket consists of a double-wrapped heat-fused polyimide tape.

Performance Features

Designed for continuous use at temperatures to 500°F (260°C) intermittent use to 650°F (430°C)

Color-coded single conductor & a double-wrapped jacket offers easy polarity identification.

Excellent abrasion, mooisture and chemical resistance.

Applications

Power plants

Kilns

Petroleum plants

Aerospace Industry

Cryogenic applications

|

|

Kapton® Shielded Tape (KAK) 600°F Wire

Very tough, durable double wrap of heat-fused polyimide tape is applied over each conductor. Insulated conductors are twisted with a stranded drain wire and the twisted construction is covered with aluminum/Kapton® tape. The outer jacket consists of a double-wrapped heat-fused polyimide tape.

Performance Features

Designed for continuous use at temperatures to 500°F (260°C) intermittent use to 650°F (430°C)

Color-coded single conductor & a double-wrapped jacket offers easy polarity identification.

Excellent abrasion, moisture and chemical resistance.

Twisted/Shielded construction minimizes electrical interference.

Applications

Power plants

Kilns

Petroleum plants

Aerospace Industry

Cryogenic applications

|

|

Polyvinyl Duplex (PP) 220°F Wire

The least expensive extension wire insulation available. The PVC individual color-coded conductors are insulated with 15 mils (nominal) of PVC, then parallel conductors are given a 20 mil PVC jacket. The jacket is easily stripped for separation of insulated conductors for assembly.

Performance Features

Designed for continuous use at temperatures to 220°F (105°C).

Good abrasion and chemical resistance.

Applications

Permanent sensor fabrication

Laboratories

Test facilities

Short-run extension leads

|

|

Polyvinyl Extruded Shielded (PAP) 220°F Wire

This construction is the same as the Polyvinyl Duplex construction except this construction has an aluminum/Mylar tape, drain wire and twisted pair. This provides isolation and eliminates internal and external noise in the circuit.

Performance Features

Designed for continuous use at temperatures to 220°F (105°C).

Shielded construction provides excellent noise protection.

Good moisture and chemical resistance; good abrasion resistance.

Applications

General plant installation

|

|

Synthetic Fiber (SFSF) 500°F Wire

Tough, heavy insulated for use where abrasion resistance on braided insulation is required. Conductors are insulated with a braided composite synthetic yarn and impregnated with a color-coded moisture resistant saturant. The insulated conductors are laid parallel and insulated with a heavy yarn composite synthetic fiber jacket, which is then coated with the same saturant.

Performance Features

Designed for continuous use at temperatures to 500°F (260°C), intermittent use to 650°F (340°C).

Excellent abrasion and good chemical resistance.

Applications

Glass & ceramic manufacturing

Heat treating

Metal working plants

Above construction can be supplied with skived Teflon® tape over each conductor prior to applying the synthetic overbraid for increased chemical resistance. Contact us for part number and ordering information. |

|

PVC Insulation & Jacket Overall Shield (UPAP) 200°F Thermocouple Extension Wire

Cable Specifications:

Conductors: 20 awg solid thermocouple extension wire

Single Insulation: 15 mils 105 degC PVC

Color Code: Jacket and individual pairs are per ANSI MC96.1

Construction: Twisted pair

Identification of pair: One conductor of each pair is numbered

Twist: Lay is approximately 2.5 inches

Overall Shield: 0.002" aluminized polyester backed tape over lapped to provide 100% coverage when flexed

Overall Drain Wire: Stranded uninsulated tinned copper in continuous contact with shield

Communications Wire: 22 awg stranded copper wire insulated and color coded orange

Ripcord: Assists in jacket removal

Jacket Insulation: 90°C flame retardant PVC

Features:

UL Listed under Subject 13

Passes IEEE 383 70,000 BTU 1 hour flame test (non-proagating)

Excellent moisture, chemical & abrasion resistance

UL PLTC 300 Volt

|

|

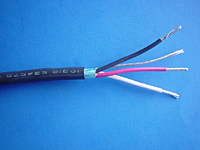

PVC Insulation & Jacket Individual & Overall Shield (UPAAP) 200°F Thermocouple Extension Wire

Cable Specifications:

Conductors: 20 awg solid thermocouple extension wire

Single Insulation: 15 mils 105°C PVC

Color Code: Jacket and individual pairs are per ANSI MC96.1

Construction: Twisted pair

Identification of pair: One conductor of each pair is numbered

Twist: Lay is approximately 2.5 inches

Pair Shield: Aluminized polyester backed tape overlapped to provide coverage when flexed

Pair Drain Wire: Stranded uninsulated tinned copper in continuous contact with shield

Overall Shield: 0.002" aluminized polyester backed tape over lapped to provide 100% coverage when flexed

Overall Drain Wire: Stranded uninsulated tinned copper in continuous contact with shield

Communications Wire: 22 awg stranded copper wire insulated and color coded orange

Ripcord: Assists in jacket removal

Jacket Insulation: 90 degC flame retardant PVC

Features:

UL Listed under Subject 13

Passes IEEE 383 70,000 BTU 1 hour flame test (non-proagating)

Excellent moisture, chemical & abrasion resistance

UP PLTC 300 Volt

|

|

PVC Insulation & Jacket Overall Shield Single Pair & Triad (PAP & UPAP) 200°F Electronic Instrument Wire

Cable Specifications:

Conductors: 7-strand copper wire

Single Insulation: 15 mils 105 degC PVC

Construction: Twisted pair/Triad

Twist: Lay si approximately 2.5 inches

Color Code: Black and White (Triad: Black, White, Black)

Overall Shield: 0.002" aluminized polyester backed tape over lapped to provide 100% coverage when flexed

Overall Drain Wire: Stranded uninsulated tinned copper in continuous contact with shield

Jacket Insulation: 90°C flame retardant PVC

Features:

UL Listed under Subject 13

Passes IEEE 383 70,000 BTU 1 hour flame test (non-proagating)

Excellent moisture, chemical & abrasion resistance

UP PLTC 300 Volt

|

|

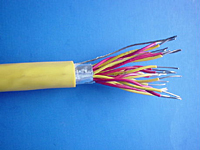

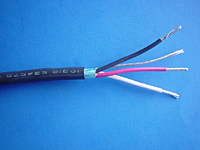

PVC Insulation & Jacket Overall Shield (UPAP) 200°F Multi-Pair Electronic Instrument Wire

Cable Specifications:

Conductors: 7-strand 20 awg copper wire

Single Insulation: 15 mils 105°C PVC

Color Code: Black and White

Construction: Twisted pairs

Identification of pair: One conductor of each pair is numbered

Twist: Lay is approximately 2.5 inches

Overall Shield: 0.002" aluminized polyester backed tape over lapped to provide 100% coverage when flexed

Overall Drain Wire: Stranded uninsulated tinned copper in continuous contact with shield

Communication Wire: 22 awg stranded tinned copper wire insulated and color coded orange

Jacket Insulation: 90°C flame retardant PVC

Features:

UL Listed under Subject 13

Passes IEEE 383 70,000 BTU 1 hour flame test (non-proagating)

Excellent moisture, chemical & abrasion resistance

UP PLTC 300 Volt

|